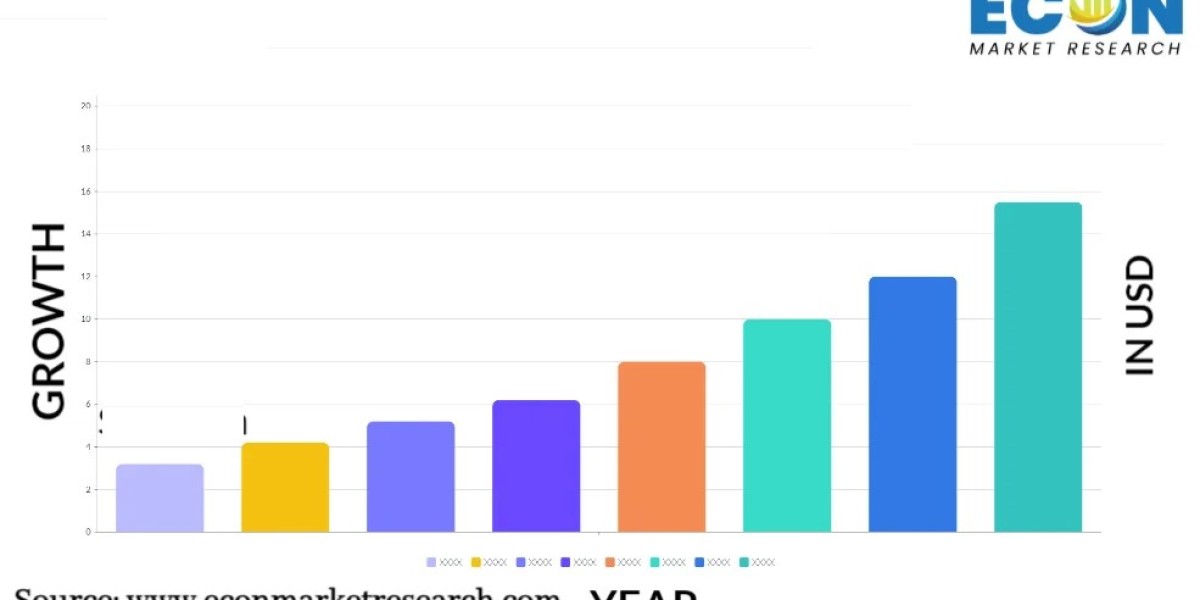

The High-Performance Plastic Additives Market is projected to reach $2,839.3 million by 2031 from $1,045.3 million in 2021, growing at a CAGR of 9.6% during the forecast period 2022-2031.

The demand for high-performance plastic additives is anticipated to grow with the increasing demand from end-user industries such as transportation, medical, electricals and electronics, packaging, and others. Furthermore, it is anticipated that during the projected period (2022-2031), the increasing adoption of high-performance plastics in the electrical and electronics industry and the growing green transportation technologies in several emerging economies, including China, India, and Thailand, are expected to further fuel the advancement of the global high-performance plastic additives market. However, the rigorous environmental standards regarding the hazardous compounds in plastics are anticipated to hinder market growth in the upcoming future.

Market Lifecycle Stage

The global high-performance plastic additives market is in the growth phase. Increased investment and research and development activities are expected to boost the market. Furthermore, due to high demand from end-user industries and rising public concerns, government regulations related to hazardous and non-degradable polymer compounds are expected to increase the demand for eco-sustainable polymers, thereby bolstering the global high-performance plastic additives market. Moreover, the global high-performance plastic additives market is expected to benefit from the growing implementation of high-performance plastics such as polytetrafluoroethylene (PTFE) for metal replacement, which promotes market expansion.

Industrial Impact

High-performance plastic additives continue to improve the supreme sliding friction, weight-saving capabilities, rigidity, high stiffness, and durability of the materials to which they are applied. As a result, these materials are gaining prominence in a variety of industries, including transportation, medical, aerospace, and electricals and electronics. One area where implementation has been significantly greater is the electrical and electronics industry, which has created opportunities for both existing market participants and market entrants.

Furthermore, high-performance plastic additives have a moderate to high impact on end-user industries; however, in the upcoming future, with increasing penetration of electrical and electronics, transportation, and other industries, the impact is anticipated to increase.

Impact of COVID-19

COVID-19 had an immediate and significant impact on the global high-performance plastic additives market because of country-wide shutdowns of manufacturing sites, labor shortages, and disruptions in supply and demand chains globally, which distorted the market. The lockdowns imposed by the governments significantly reduced raw material productivity due to a shortage of operations in many regions throughout the world. The electrical and electronics, transportation, and other end-user sectors have been in a slowdown for the last couple of years. The global demand for high-performance plastic additives has been severely impacted by these market downturns in the end-user industries. However, the market is anticipated to recover and is expected to rise gradually over the forecast period.

Market Segmentation:

Segmentation 1: by End User

- Transportation

- Medical

- Electrical and Electronics

- Packaging

- Others

The electrical and electronics industry is the prominent end-user segments in the global high-performance plastic additives market.

Segmentation 2: by Plastic Type

- Fluoropolymers

- High-performance Polyamides

- Sulfone Polymers

- Liquid Crystal Polymers

- Polyimides

- Others

The global high-performance plastic additives market is estimated to be led by high-performance polyamide in terms of plastic type.

Segmentation 3: by Additive Type

- Plasticizers

- Flame Retardants

- Lubricants

- Anti-Oxidants

- Stabilizers

- Others

The global high-performance plastic additives market is estimated to be led by flame retardants and others in terms of additive type.

Segmentation 4: by Region

- North America - U.S., Canada, and Mexico

- Europe - Germany, France, Italy, Spain, and Rest-of-Europe (RoE)

- China

- U.K.

- Asia-Pacific and Japan - Japan, India, South Korea, and Rest-of-Asia-Pacific and Japan

- Rest-of-the-World (ROW)

In the global high-performance plastic additives market, Asia-Pacific and Japan and China are anticipated to gain traction in terms of high-performance plastic additives production, owing to the continuous growth in electrical and electronics production and the presence of key manufacturers in the regions.

Recent Developments in the Global High-Performance Plastic Additives Market

- In September 2022, SABIC unveiled the LNP THERMOCOMP AM DC0041XA51 compound at InnoTrans 2022 in Berlin, Germany. It is an innovative carbon fiber-reinforced, flame-retardant (FR) substance appropriate for pellet-fed additive manufacturing (PFAM/), which is fully complied with E.U. and U.S. rail fire safety requirements.

- In September 2021, 3M expanded its line of boron nitride cooling fillers with new product grades, i.e., boron nitride cooling filler agglomerates CFA 100 and boron nitride cooling filler agglomerates CFA 150. Both consist of soft boron nitride agglomerates, which are used to enhance isotropic thermal conductivity and have applicability in automotive, electrical, and electronic devices and components.

- In October 2022, during K 2022 in Dusseldorf, Germany, Evonik Industries AG displayed its most recent viable strategies for the polymers and foam industries. INFINAM PA, a new and improved grade of PA-12 powders with drastically reduced CO2 emissions for fused deposition 3D printing technologies, was also displayed.

Demand – Drivers and Limitations

The following are the demand drivers for the global high-performance plastic additives market:

- Rising Demand from the Automotive Industry

- Replacement of Conventional Materials in a Variety of Applications

- Development of Innovative Applications and Rising Demand from the Electronics Industry

The market is expected to face some limitations as well due to the following challenges:

- Strict Government Regulations for the Plastic Industry

- High Cost and Rising Price Volatility of Raw Materials

Get Free Sample Report - https://bisresearch.com/requestsample?id=1431type=download

Key Market Players and Competition Synopsis

The companies that are profiled have been selected based on inputs gathered from primary experts, analyzing companies’ high-performance plastic additives coverage, product portfolio, and market penetration.

The global high-performance plastic additives market has been segmented into different additive types, among which flame retardants captured around 20.2% of the market as of 2021. The lubricants segment accounted for around 14.7%, antioxidant segment accounted for 10.0%, stabilizers accounted for 11.7%, plasticizers accounted for 3.7%, and other additive types accounted for 39.7% of the total demand in 2021 in terms of value.

Key Companies Profiled

- Solvay S.A.

- Evonik Industries AG.

- Colloids Ltd.

- SABIC

- Ensinger

- L.Brueggemann GmbH Co. KG

- Americhem, Inc.

- Colortech Inc.

- Tosaf Compounds Ltd.

- Arkema

- BASF SE

- 3M

- SUQIAN UNITECH CORP., LTD.

- Nouryon

- Avient Corporation

- Kemipex

- Advanced Polymer Solutions, LLC

- NEWOS GmbH

- Ceramer GmbH

- Karan Industrial Group

How can this report add value to an organization?

Product/Innovation Strategy: The product segment helps the reader understand the different high-performance plastic types such as fluoropolymers, high-performance polyamide, sulfone polymers, liquid crystal polymers, and polyimides, among others (PEEK, PLA, etc.), and high-performance plastic additive types, such as plasticizers, flame retardants, lubricants, anti-oxidants, and stabilizers, involved in the production of high-performance plastics. Moreover, the study provides the reader with a detailed understanding of the global high-performance plastic additives market based on the end user (transportation, medical, electricals and electronics, packaging industry, and others). Additionally, high-performance plastic additives are gaining traction in end-user industries on the back of sustainability concerns and are also being used to modify the properties of different polymers.

Growth/Marketing Strategy: The global high-performance plastic additives market has seen major development by key players operating in the market, such as business expansions, partnerships, collaborations, mergers and acquisitions, and joint ventures. The favored strategy for the companies has been product developments, business expansions, and acquisitions to strengthen their position in the global high-performance plastic additives market. For instance, in September 2021, Solvay S.A. launched a brand-new segment of build panels for additive manufacturing (AM) that was anticipated to be marketed under the Ajedium brand. In additive manufacturing techniques, build panels or trays are utilized as the fundamental substrates on which the molded AM ?ber strands are constructed or 3D printed. Ajedium Build Sheets are available from Solvay in a variety of configurations and can be made from a broad range of high-performance polymers, including Udel PSU, Radel PPSU, and KetaSpirePEEK. These sheets offer superior sturdiness, thermal performance, bond strength, rigidity, and uniformity.

Competitive Strategy: Key players in the global high-performance plastic additives market analyzed and profiled in the study involve high-performance plastic additive manufacturers and the overall ecosystem. Moreover, a detailed competitive benchmarking of the players operating in the global high-performance plastic additives market has been done to help the reader understand how players stack against each other, presenting a clear market landscape. Additionally, comprehensive competitive strategies such as partnerships, agreements, acquisitions, and collaborations will aid the reader in understanding the untapped revenue pockets in the market.

Analyst View

According to Sachin Singh, Lead Analyst, BIS Research, “High-performance plastic additives play a significant role in transportation, medical, electricals and electronics, packaging, and aerospace, as well as other applications. High-performance plastic additives have been adopted by these end users as it improves the sliding friction, weight-saving capabilities, rigidity, high stiffness, and durability of the substrates to which they are applied. Also, the expansion of the transportation industry, increasing electrical and electronics products adoption, and demand from the packaging industry are anticipated to drive the market during the forecast period.”

You May Also Like -