Modern manufacturing is all about precision, efficiency, and speed. Assembly fixtures play a pivotal role in achieving these goals. They are essential tools that ensure components are correctly aligned and securely held during the manufacturing process. Let’s explore why assembly fixtures are indispensable and how they contribute to the success of modern production lines.

What Are Assembly Fixtures?

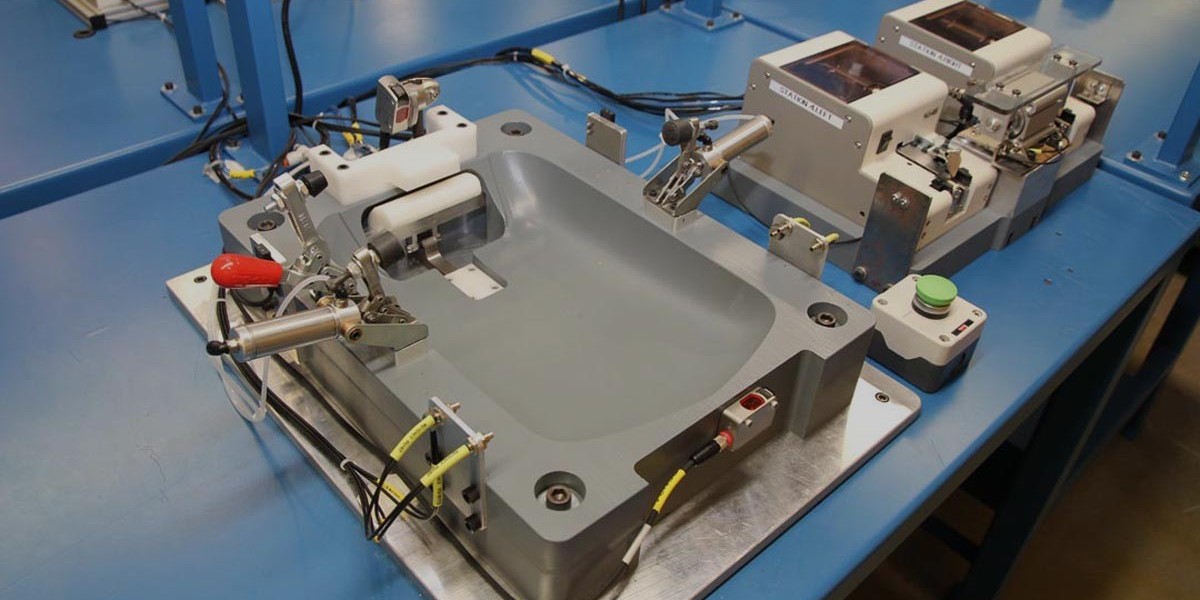

Assembly fixtures are specialized tools or devices used to hold, position, and align parts during manufacturing. These fixtures help workers or automated systems carry out assembly processes with precision, reducing errors and enhancing consistency.

The Role of Assembly Fixtures in Manufacturing

Ensuring Consistency

One of the primary roles of assembly fixtures is to maintain uniformity across all products. They ensure that every component fits perfectly, reducing discrepancies in production.

Improving Efficiency

With assembly fixtures, manufacturers can speed up the production process without compromising on quality. These tools minimize the time spent on adjustments and ensure a smooth workflow.

Enhancing Safety

Assembly fixtures reduce the risk of accidents by holding components securely in place. This is especially important in high-speed manufacturing environments where safety is a top priority.

Types of Assembly Fixtures

Manual Fixtures

These are operated by workers and are ideal for small-scale production or intricate assemblies.

Automatic Fixtures

Used in large-scale production, these fixtures are integrated with automation systems to enhance productivity.

Modular Fixtures

These versatile fixtures can be adjusted or reconfigured to handle different components, making them cost-effective and adaptable.

Key Benefits of Assembly Fixtures

Increased Precision

Assembly fixtures help manufacturers achieve the highest level of precision, ensuring components are perfectly aligned and assembled.

Cost Reduction

By reducing errors and rework, assembly fixtures lower overall production costs. They also optimize material usage, saving resources.

Scalability

Manufacturers can scale production efficiently by using automated assembly fixtures, meeting market demands without compromising quality.

Industries That Rely on Assembly Fixtures

Automotive Manufacturing

In the automotive sector, assembly fixtures are used for tasks like welding and assembling complex components, ensuring vehicles are safe and reliable.

Aerospace Industry

Precision is critical in aerospace, and assembly fixtures help maintain the strict tolerances required for aircraft components.

Electronics

Fixtures are essential in assembling intricate electronic components, ensuring reliability and performance in devices.

Challenges in Using Assembly Fixtures

Initial Investment

High-quality fixtures can be expensive, but the long-term benefits often outweigh the upfront costs.

Maintenance Requirements

Regular maintenance is crucial to keep fixtures in top condition, ensuring they deliver consistent performance.

How to Choose the Right Assembly Fixtures

Assess Your Needs

Understand the requirements of your manufacturing process. Consider the complexity of components, production volume, and precision needs.

Opt for Quality

Invest in high-quality fixtures made from durable materials. This ensures long-term reliability and performance.

Consider Automation

If scalability is a priority, choose fixtures that can integrate with automated systems for greater efficiency.

Innovations in Assembly Fixtures

Smart Fixtures

The integration of IoT technology has led to the development of smart fixtures that can monitor performance and provide real-time data.

Custom Fixtures

Custom-designed fixtures cater to specific manufacturing needs, offering unparalleled precision and efficiency.

The Future of Assembly Fixtures

As technology advances, assembly fixtures are becoming more intelligent and efficient. Innovations like AI-powered fixtures and 3D-printed designs are paving the way for a new era in manufacturing.

Conclusion

Assembly fixtures are the backbone of modern manufacturing, ensuring precision, efficiency, and safety. By investing in the right fixtures, manufacturers can optimize production, reduce costs, and maintain high-quality standards. As industries continue to evolve, assembly fixtures will remain a critical component of successful manufacturing processes.