In the world of bulk storage and transport, efficiency and safety are paramount. Whether it’s grains being stored for later use, powders being transported to manufacturing facilities, or chemicals requiring carefully controlled environments, the choice of storage materials can significantly impact overall operational success. Among the myriad of options available, Mahira Polyglobal LLP offers high-quality PP jumbo bags—also known as big plastic bags—that emerge as the ultimate solution. Designed to offer enhanced durability, greater capacity, and a host of features tailored for specific storage needs, these big plastic bags have revolutionized bulk cargo handling across various industries.

The Versatility of PP Jumbo Bags

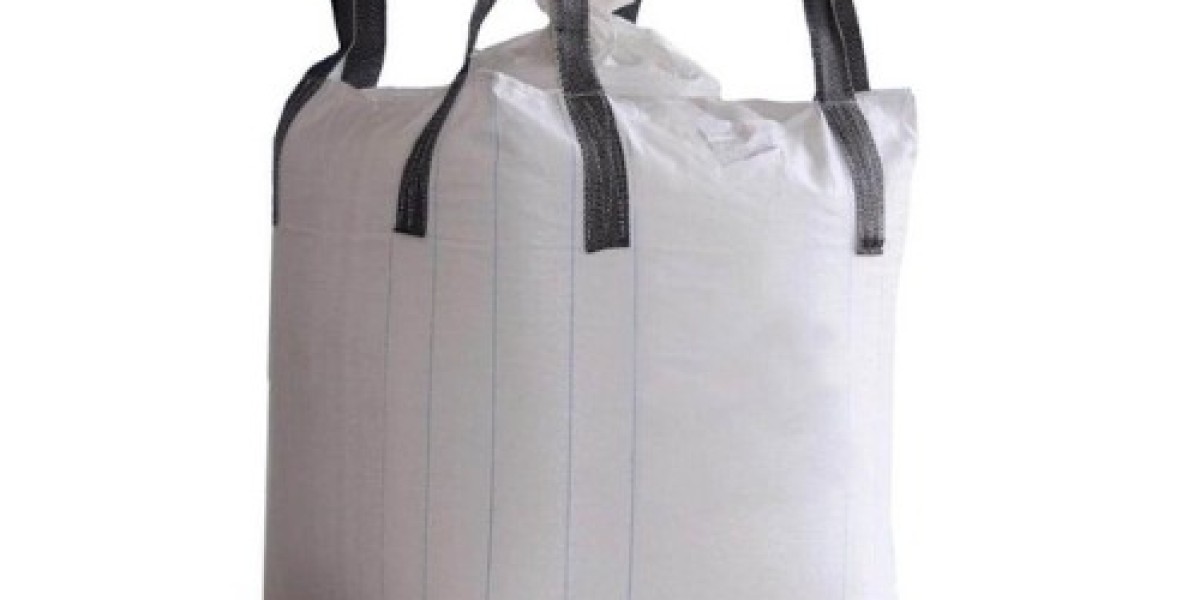

PP jumbo bags, crafted primarily from high-density polypropylene (PP), offer unparalleled versatility compared to traditional storage options. Their design allows them to hold substantial weights, making them ideal for storing bulk powders, grains, and even hazardous chemicals. Many industries—from agricultural to chemical manufacturing—benefit from these big plastic bags because they come in various sizes and configurations to suit a range of specific requirements. For instance, a Big plastic bag can be designed with a filling spout or a discharge outlet, facilitating easier handling and transportation. This customization means that businesses can select bags that meet their unique specifications without having to compromise on safety or efficiency.

The construction of PP jumbo bags also contributes to their flexibility. They are often woven, making them breathable and resistant to moisture, which is crucial when storing organic materials like grains that can spoil if kept in damp conditions. Ventilation holes can be included to ensure that even delicate powders remain safe from clumping or degradation. Moreover, the lightweight nature of these bags aids in reducing transport costs and makes manual handling less burdensome for workers—a significant advantage in warehouses and industrial sites where efficiency is key.

Robustness for Heavy-Duty Applications

Another compelling reason for selecting PP jumbo bags over traditional storage methods is their incredible strength. These big plastic bags are engineered to withstand heavy loads, often supporting weights of up to 2,000 kilograms, depending on the design. The durability of these bags is further enhanced by the ability to handle various environmental conditions without compromising structural integrity. For example, businesses do not have to worry about their contents being exposed to UV rays, moisture, or extreme temperatures, as appropriate treatments can be applied to the bags during production.

For those storing or transporting hazardous materials, the robustness and safety features of PP jumbo bags are even more critical. Many bags can be designed specifically to comply with safety regulations that govern the storage of chemicals. Features like double-stitched seams and sealed bottoms prevent leaks or spills, thus mitigating the risk of contamination and ensuring that both workers and the environment remain safe. The reliability of these Big plastic bags for dangerous products also means they can be reused multiple times before needing to be replaced, an attribute that can significantly cut down operational costs over time.

Eco-Friendly Innovations in Jumbo Bag Production

As global awareness regarding environmental issues becomes more pronounced, many industries are making strides toward sustainable practices. The production of PP jumbo bags has also evolved to embrace eco-friendliness. Although polypropylene itself is a plastic material, which can cause environmental concerns, manufacturers are increasingly focusing on approaches that minimize the ecological footprint of these big plastic bags. For instance, many companies are working to reduce waste during production and offering recycling programs for used bags.

Moreover, the durability that comes with these bags means they typically have a long lifecycle. The longer a bag can be used, the less frequently new bags need to be produced, thereby conserving resources and energy. Some manufacturers even create bags designed for easier recycling, aiming to close the loop in the production and waste cycle. Sustainable practices are becoming a defining trend in the use of PP jumbo bags, making them a more responsible option for businesses that aim to demonstrate corporate social responsibility.

Economical and Efficient Storage Solution

With their strength, customizability, and eco-friendly designs, PP jumbo bags are not just practical; they are also economically beneficial. First and foremost, the cost of purchasing these Plastic big bags is typically lower compared to other bulk storage solutions such as bins or drums, which require larger capital investment. Additionally, due to their lightweight design, transporting filled jumbo bags incurs lower shipping costs—especially important when dealing with heavy bulk materials.

From a storage perspective, the stackable nature of PP jumbo bags maximizes warehouse space. When not in use, they can be folded flat, making them easy to store and transport back to the production site. This space-saving quality is invaluable for businesses looking to optimize their storage capacities. In summary, PP jumbo bags tackle the dual challenges of cost-effectiveness and spatial efficiency, rendering them an essential solution for manufacturers and distributors that manage bulk materials.

Conclusion

PP jumbo bags are undoubtedly the ultimate answer for the challenges presented by bulk storage and transport in modern industries. Their robustness, versatility, and economical benefits position them as a practical choice for a wide range of applications—from agricultural uses and food storage to handling industrial chemicals. As manufacturers increasingly implement eco-friendly practices, these big plastic bags have become not only a functional solution but also a responsible choice for conscientious businesses. The advent and widespread adoption of PP jumbo bags signify a transition toward more efficient and sustainable bulk handling methods, ensuring that industries can achieve their operational goals while maintaining a strong commitment to safety and environmental responsibility.

Frequently Asked Questions

What are the typical dimensions and weight capacities of PP jumbo bags?

PP jumbo bags come in a wide range of sizes, but standard dimensions often include a height from 90cm to 120cm and a width of about 90cm. Their weight capacities can range from 500kg to 2,000kg, depending on the bag's design and material.Can PP jumbo bags be customized for specific applications?

Yes, many manufacturers offer customization options, such as different filling and discharge mechanisms, varying fabric weights, and unique printing for branding purposes.How should PP jumbo bags be stored when not in use?

PP jumbo bags should be stored in a cool, dry place away from direct sunlight to prevent wear and tear. It’s advisable to store them flat or rolled up to avoid deformation.Are there any recycling options available for used PP jumbo bags?

Many manufacturers provide recycling programs for used PP jumbo bags. It is crucial to check with your supplier to understand the available recycling options in your area.