In recent years, the growing concern over environmental issues has prompted industries worldwide to seek sustainable alternatives in their manufacturing processes. One such alternative gaining popularity is polypropylene (PP) sheets. These sheets not only meet various industrial needs but also align with the principles of responsible manufacturing. This article will explore the benefits, applications, and the emerging trends associated with environmentally friendly PP sheets, particularly in the context of their production in India. Additionally, we will discuss the Cost of plastic sheets and the PP price in India to provide a comprehensive overview of the market landscape.

Understanding Polypropylene Sheets

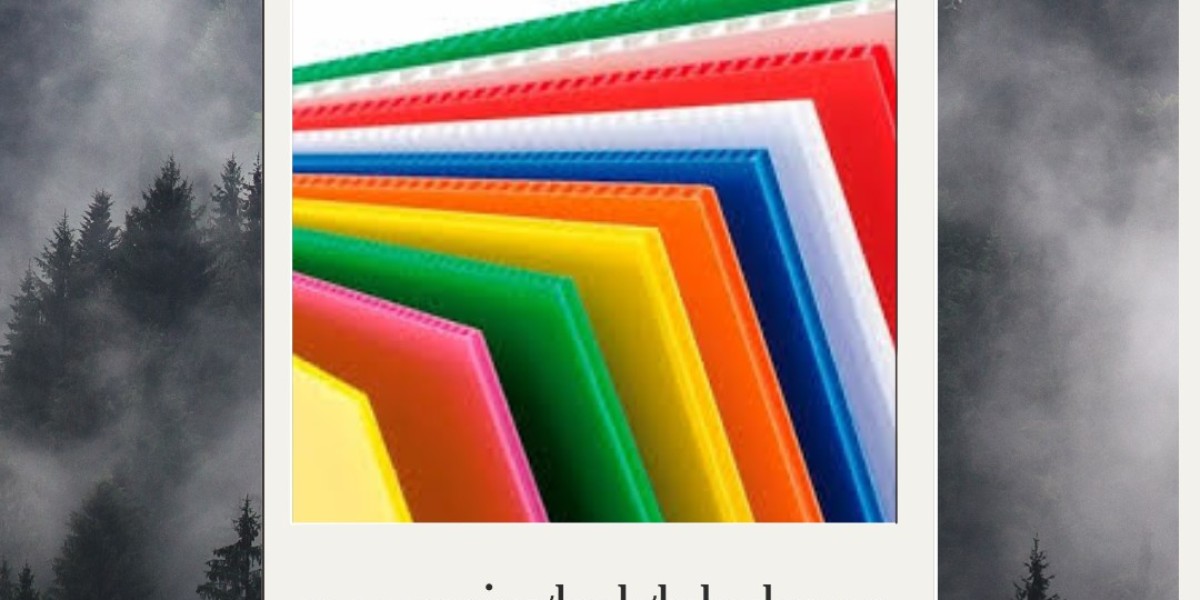

Polypropylene sheets are versatile thermoplastic materials known for their strength, lightweight nature, and resistance to moisture and chemicals. Their unique properties make them suitable for a wide range of applications, from packaging to automotive components. With the increasing awareness of environmental sustainability, manufacturers are looking to utilize PP sheets that minimize environmental impact.

PP sheets can be produced using recycled polypropylene, which reduces the reliance on virgin materials and lowers carbon footprints. The production process of these sheets can also be designed to reduce energy consumption and waste generation. As a result, they present a viable solution for companies striving for eco-friendliness in their operations.

The Importance of Responsible Manufacturing

Responsible manufacturing refers to practices that prioritize environmental sustainability, social responsibility, and economic viability. In today's world, consumers and regulatory bodies alike are increasingly demanding that manufacturers adopt sustainable practices. Using environmentally friendly materials like PP sheets is a significant step toward achieving this goal.

By incorporating polypropylene sheets in India into their production processes, manufacturers can not only enhance their sustainability credentials but also meet the growing demand for eco-friendly products. This transition requires a commitment to responsible sourcing, efficient production methods, and innovative design practices that minimize waste and maximize resource efficiency.

Environmental Benefits of PP Sheets

The environmental benefits of using PP sheets are manifold. Firstly, they are recyclable, meaning that post-consumer products can be processed and reused in manufacturing new sheets. This closed-loop system reduces the need for virgin materials and lessens the burden on landfills.

Secondly, polypropylene sheets are free from harmful additives, making them safer for the environment compared to some other plastic alternatives. They do not release toxic substances during their lifecycle, which contributes to a healthier ecosystem. Additionally, the production of PP sheets can be optimized to use less energy and water, further reducing their environmental impact.

Moreover, the lightweight nature of PP sheets contributes to lower transportation emissions. Since they require less energy to transport than heavier materials, using PP sheets can help manufacturers decrease their overall carbon footprint.

Applications of Environmentally Friendly PP Sheets

Polypropylene sheets have a wide range of applications across various industries. In packaging, they are used for food containers, protective coverings, and disposable items, where their moisture resistance and durability come in handy. Many companies are transitioning to eco-friendly PP packaging solutions as consumers become more environmentally conscious.

In the construction sector, PP sheets are utilized for insulation, waterproofing, and as barriers in construction projects. Their resistance to moisture and chemicals makes them suitable for various building applications, contributing to energy efficiency and durability.

The automotive industry is another significant user of polypropylene sheets, employing them in interior components, dashboard covers, and under-hood applications. By opting for environmentally friendly PP sheets, automakers can enhance the sustainability of their products while maintaining performance standards.

The Market for Polypropylene Sheets in India

The demand for polypropylene sheets in India has been steadily rising, driven by the growth of industries that require sustainable solutions. The country's manufacturing sector is increasingly focusing on eco-friendly practices, and the adoption of PP sheets is a part of this trend. India has a robust market for PP sheets, which can cater to diverse industrial needs while promoting sustainability.

The cost of plastic sheets in India can vary depending on several factors, including the type of plastic, thickness, and production methods. However, as more manufacturers begin to use recycled materials in their production processes, the costs are expected to stabilize. Additionally, government initiatives promoting recycling and sustainable manufacturing practices may further influence pricing.

Pricing Trends: PP Sheets in India

When discussing the PP price in India, it is essential to consider the factors that affect the pricing of these sheets. The cost of raw materials, production techniques, and market demand all play a significant role in determining the price. As the demand for environmentally friendly products continues to rise, manufacturers are adapting to this shift, leading to a competitive market landscape.

Manufacturers that invest in innovative technologies and sustainable practices may face initial costs, but these investments can yield long-term savings through increased efficiency and reduced waste. Moreover, the transition to using recycled materials in producing PP sheets can lead to significant cost reductions over time.

Challenges in Adopting Eco-Friendly Practices

Despite the numerous benefits of using environmentally friendly PP sheets, several challenges remain in their widespread adoption. The initial costs associated with switching to sustainable materials can deter some manufacturers, particularly smaller companies with limited resources. However, as the market for eco-friendly materials expands, economies of scale may help reduce these costs.

Another challenge is the need for proper recycling infrastructure. While PP sheets are recyclable, the availability of facilities capable of processing these materials varies. The development of a comprehensive recycling system in India is crucial for maximizing the environmental benefits of PP sheets.

Furthermore, educating consumers and businesses about the advantages of using eco-friendly materials is essential. Increased awareness can drive demand for sustainable products, encouraging manufacturers to invest in responsible practices.

The Future of Polypropylene Sheets

The future of polypropylene sheets looks promising, especially as industries continue to embrace sustainability. Innovations in production techniques, such as the use of biodegradable additives and advanced recycling technologies, can enhance the environmental profile of PP sheets.

The government's support for sustainable manufacturing practices, including subsidies for using recycled materials, can further incentivize manufacturers to adopt eco-friendly solutions. As the market for Polypropylene sheets in India expands, the emphasis on sustainability will likely continue to shape product development and manufacturing processes.

Conclusion

In conclusion, environmentally friendly PP sheets represent a significant advancement in responsible manufacturing. Their versatility, recyclability, and reduced environmental impact make them an ideal choice for various industries seeking sustainable alternatives. The increasing demand for eco-friendly products, coupled with the ongoing efforts to improve recycling infrastructure and reduce costs, positions polypropylene sheets as a viable option for manufacturers in India and beyond.

As the world moves toward a more sustainable future, the adoption of polypropylene sheets will play a crucial role in achieving responsible manufacturing practices. By investing in these materials, manufacturers can not only meet consumer demands but also contribute to a healthier planet. Ultimately, the transition to environmentally friendly PP sheets is a win-win for businesses and the environment, paving the way for a sustainable future in manufacturing.

Frequently Asked Questions (FAQs)

Can polypropylene sheets be customized?

Yes, polypropylene sheets can be customized in terms of thickness, color, size, and printing options to meet specific requirements for various applications.How do I clean and maintain polypropylene sheets?

PP sheets can be easily cleaned with mild soap and water. Avoid using harsh chemicals or abrasive cleaners, as they may damage the surface. For heavy dirt or stains, a soft cloth or sponge can be used.What is the temperature range for using polypropylene sheets?

Polypropylene sheets have a temperature tolerance of approximately -20°C to 80°C (-4°F to 176°F). However, prolonged exposure to high temperatures may affect their structural integrity.