Because of the speed of the technology and the relatively low cost involved, the use of three-dimensional printing in the manufacturing industry is becoming an increasingly common practice. It is the answer that is ideal for businesses that want to create small orders of prototype models of new products quickly but do not want to invest a significant amount of money in doing so, and a number of different businesses offer it. It is the ideal solution for businesses that want to create small orders of prototype models of new products. These benefits include the opportunity to test and evaluate a variety of different prototypes, in addition to the fact that it is more convenient overall. However, does this technology have a negligible impact on the natural environment in which it operates?

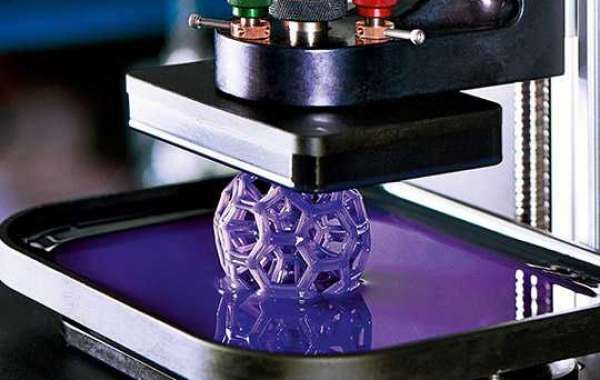

When someone talks about something being "printed in 3D," what exactly do they mean by that term? The process of printing three-dimensional objects is another name for additive manufacturing (AM). The procedure starts with the creation of a template for the design using computer-aided manufacturing (CAM), and then What is 3D Printing moves on to the application of material filaments, which are typically made of plastic. CNC machining makes use of digitized data, computers, and a CAM program in order to control, automate, and monitor the motions of a machine. This technique is known as computer numerical control (CNC).

As soon as everything that is required for the 3D printing process has been prepared and is in a state of readiness, successive layers of new material will be added in order to construct the completed design. This will continue until the finished product has been produced. This process will be repeated until the final product has been manufactured. Grinding, melting, and extruding different kinds of plastics were not possible processes in the past; however, in today's world, all three of these steps are required in order to produce filament. In the past, grinding was the only process that was possible. Having said that, there is still a possibility that this won't work properly with some printers or with particular varieties of plastic.

Less Waste

The traditional methods of manufacturing that have been used up to this point are going to be phased out and replaced by 3D printing as the manufacturing process moves forward. However, the process does lead to the production of some byproducts that are bad for the environment, and these should be avoided at all costs. These byproducts should not be produced at all, so it is imperative that they be avoided at all costs. It is possible that in the not-too-distant future, we will be able to modify 3D printers in such a way that they produce fewer harmful byproducts while they are operating, thus significantly improving the green credentials of these machines. This would be a significant step forward in terms of the environmental impact that these machines have. In terms of the effect that these machines have on the surrounding environment, this would be a significant advance in the right direction. This would lead one to believe that corporations, research facilities, and educational institutions located in different parts of the world have already begun conducting their own experiments and manufacturing their own products. Evidence such as this lends credence to the proposition that employing the use of this product has a positive impact on the natural world.

This serves as the primary pillar upon which the argument is built, so it's important to keep that in mind.

It is possible to carry out three-dimensional printing in a manner that is less disruptive to the natural world, which is one of the most compelling selling points of this innovative form of manufacturing. The government provides assistance to businesses that are willing to protect the environment, in addition to the obvious benefits that these companies provide for the planet. In other words, the planet benefits from both the companies and the government. This is because it has not yet developed to its full potential, which has led to this situation. When one takes into consideration the fact that, it is simple to understand why this is the case. Because it is reasonable to anticipate that additional benefits will become apparent as technology advances, this will provide us all with yet another reason to make 3D printing the one to watch over the next few years. This will make 3D printing the one to watch over the next few years. Because of this, 3D printing will be the trend to keep an eye on over the next few years. This is because additive manufacturing is also known as the process of printing three-dimensional objects one layer on top of the next.

The reason for this is due to the fact that additive manufacturing is also known as the process. The process of three-dimensional printing can be broken down into the following categories in terms of the ways in which it interacts with the natural world:

Material Efficiency: When compared to other manufacturing processes, 3D printing has the potential to have a higher material efficiency than other manufacturing methods. This is because 3D printing uses less material. This is especially true when compared to production methods that are considered to be more conventional. It makes it possible to manufacture items on demand, which eliminates the need for stockpiling and reduces the amount of inventory that must be kept on hand. This eliminates the need for stockpiling and makes it possible to manufacture items on demand.