Monosodium glutamate (MSG) is more than just a pantry staple in Asian cuisine. It is a cornerstone ingredient for the global food industry, widely used for its ability to enhance savory flavors. As the demand for processed and convenience foods continues to rise globally, the role of monosodium glutamate suppliers has become increasingly critical.

MSG is the sodium salt of glutamic acid, a naturally occurring amino acid found in tomatoes, cheese, and mushrooms. Known for its distinct umami taste, MSG enhances the flavor of foods without adding extra calories or sugar, making it a valuable additive in a wide range of culinary applications.

In this article, we examine the strategic importance of monosodium glutamate suppliers in the global flavor enhancer market, including sourcing, supply chain management, regulations, technological advancements, and market outlook.

Understanding the Global Flavor Enhancer Market

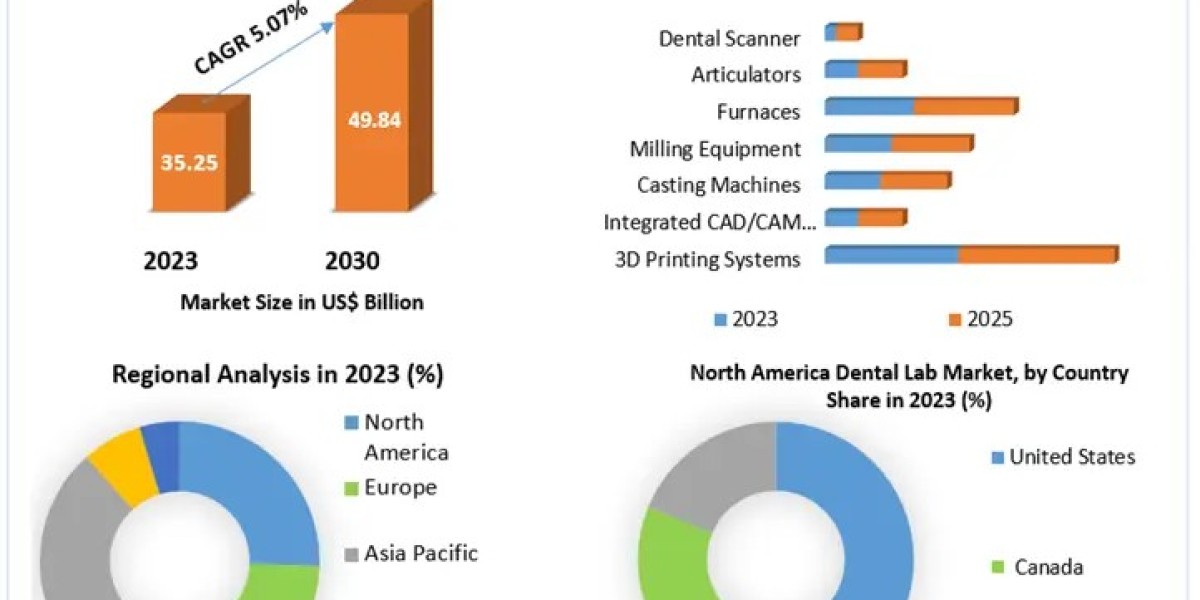

Due to rising consumption of processed and ready-to-eat meals, the flavour enhancer market is expected to reach over USD 12 billion globally by 2030. MSG and other flavour enhancers are essential for improving taste profiles, particularly in plant-based, low-fat, and low-sodium food substitutes.

Important Market Drivers:

Growth in restaurant and fast food chains

Growth of the packaged food sector

Growing need in emerging economies for reasonably priced flavour solutions

Consumer tastes are shifting in favour of savoury and umami-rich meals.

Consequently, suppliers of monosodium glutamate are essential to preserving the consistency, safety, and flavour integrity of products.

The Role of Monosodium Glutamate Suppliers

1. Guaranteeing Purity and Quality

Reputable MSG providers have to follow stringent global guidelines like:

For quality control, ISO 9001

Regarding food safety, FSSC 22000

Kosher and Halal certificates

Allergen-free and non-GMO statements

To make sure that their MSG satisfies industry standards for performance and safety, suppliers make significant investments in R&D and quality control.

2. Production that is Scalable and Sustainable

Using Corynebacterium glutamicum strains, sugars are fermented to produce MSG. Leading providers of monosodium glutamate today prioritise sustainable practices:

Reducing the carbon footprint

Utilising feedstocks that are renewable

Increasing the effectiveness of fermentation

One of the biggest manufacturers of MSG, Ajinomoto Co., for instance, has pledged to reach net-zero carbon emissions by 2050.

3. International Logistics and Distribution

In order to satisfy the increasing demand from around the world, effective supply chain logistics are essential. Suppliers need to oversee:

Export laws and bulk manufacturing

Storage in facilities with climate control

On-time delivery to distributors, retailers, and food producers

To expedite product supply, numerous MSG suppliers run regional centres in North America, Europe, and Asia.

4. Regulatory Compliance and Transparency

While MSG has been declared safe by health organizations such as the FDA, EFSA, and WHO, it still requires transparent labeling and communication. Trusted monosodium glutamate suppliers ensure compliance with:

FDA regulations in the U.S.

EFSA guidelines in Europe

FSSAI regulations in India

CFIA standards in Canada

Clear documentation and traceability are essential to maintain consumer trust and legal compliance.

New Developments in MSG Manufacturing

As clean-label and plant-based movements gain traction, MSG providers are making investments in innovative production techniques:

Fermentation using biotechnology with non-GMO strains

enhanced extraction from organic sources, such as fungus and seaweed

Improved crystallisation methods to increase solubility and lessen bitterness

These developments meet the demands of both contemporary food producers and consumers.

MSG's Use in the Food Industry

There are several food categories that employ MSG:

Snack foods include savoury snack mixes, chips, and crackers.

Broths and Soups: Gives boxed soups a deeper flavour

Processed Meats: Gives cured meats, gammon and sausages their umami flavour.

Ready-to-Eat Meals: Instant noodles and frozen entrees with balanced flavours

Sauces, dressings, and seasoning powders all contain condiments.

Food scientists and chefs love it because it can improve flavour without adding more fat or sodium.

Challenges Facing Monosodium Glutamate Suppliers

Despite widespread use, MSG faces challenges that suppliers must navigate:

Consumer Misconceptions: Misinformation about MSG’s health effects can influence buying decisions.

Price Volatility: Fluctuations in raw material costs and logistics can affect pricing.

Regulatory Shifts: New health labeling laws and import regulations require ongoing adaptation.

Suppliers are addressing these challenges through educational campaigns, transparent labeling, and continuous process improvement.

Market Outlook and Opportunities

A recent MarketsandMarkets analysis projects that between 2024 and 2030, the demand for monosodium glutamate will increase at a compound annual growth rate (CAGR) of 4.8%. Growth will be especially robust in:

Asia-Pacific (India, Indonesia, China)

Africa and the Middle East

Latin America

Strategic alliances, private-label manufacturing, and expansion into clean-label MSG alternatives are some ways providers are leveraging market opportunities.

How to Choose the Right Monosodium Glutamate Supplier

Food makers should take into account the following when choosing a bulk source for MSG:

Verified industry certificates

Dependability of the supply chain

Scalability for large orders

Private labelling and personalised packaging

Clear testing reports and documentation

Reputable suppliers of monosodium glutamate provide complete assistance, from product delivery to technical advice.

Conclusion

As the demand for flavor enhancers continues to rise, monosodium glutamate suppliers are at the forefront of innovation, sustainability, and global distribution. From ensuring product safety to embracing new technologies, these suppliers are critical to the evolving needs of the modern food industry.

By sourcing MSG from reputable suppliers, food manufacturers can deliver superior taste, consistency, and value to consumers around the world. In the coming years, strategic partnerships and sustainable practices will continue to shape the role of MSG suppliers in the global flavor enhancer market.