Market Overview:

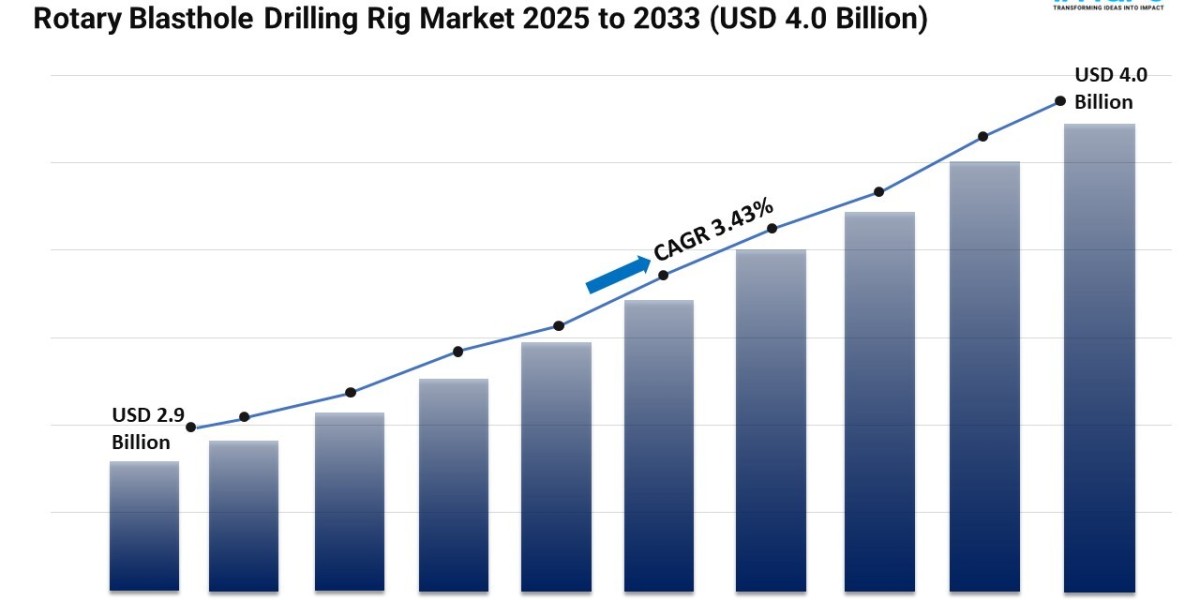

The rotary blasthole drilling rig market is experiencing rapid growth, driven by automation & remote operations, sustainability & electrification, and digitalization & data analytics. According to IMARC Group's latest research publication, "Rotary Blasthole Drilling Rig Market Report by Type (Large-range Drilling Rig, Mid-range Drilling Rig, and Others), Power (Electric, Diesel, Hybrid), Application (Quarries, Open-Pit Mining, and Others), and Region 2025-2033, The global rotary blasthole drilling rig market size reached USD 2.9 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 4.0 Billion by 2033, exhibiting a growth rate (CAGR) of 3.43% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/rotary-blasthole-drilling-rig-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Factors Affecting the Growth of the Rotary Blasthole Drilling Rig Industry:

- Automation & Remote Operations:

The rotary blasthole drilling rig market is undergoing a significant transformation with the increasing adoption of automation and remote operation technologies. Driven by the need to enhance safety, improve efficiency, and reduce operational costs, mining companies are investing in drilling rigs equipped with advanced automation features. This includes autonomous drilling capabilities, remote control systems, and real-time data analytics that enable operators to monitor and control drilling operations from a centralized control room. The integration of sensors, GPS technology, and machine learning algorithms allows for precise drilling, optimized drill patterns, and reduced human error. Furthermore, remote operation capabilities are enabling mining companies to conduct drilling activities in hazardous or remote locations without putting personnel at risk. This trend is not only improving productivity and safety but also enabling mining companies to optimize resource utilization and reduce their environmental footprint. As the demand for minerals and metals continues to grow, the adoption of automation and remote operation technologies will become increasingly crucial for the rotary blasthole drilling rig market, driving innovation and shaping the future of mining operations.

- Sustainability & Electrification:

The global push for sustainability and the reduction of greenhouse gas emissions is significantly impacting the rotary blasthole drilling rig market. Mining companies are increasingly focusing on adopting environmentally friendly drilling solutions, including electric and hybrid drilling rigs. This shift is driven by the need to comply with stringent environmental regulations and meet the growing demand for sustainable mining practices. Electric drilling rigs offer several advantages, including reduced noise pollution, lower emissions, and improved energy efficiency. Furthermore, the integration of energy recovery systems and the use of renewable energy sources are further enhancing the sustainability of drilling operations. Manufacturers are also focusing on developing drilling rigs with improved fuel efficiency and reduced water consumption. The implementation of advanced filtration systems and dust suppression technologies is also contributing to cleaner and safer drilling operations. As the mining industry continues to prioritize sustainability, the demand for electric and environmentally friendly rotary blasthole drilling rigs will continue to rise, driving innovation and shaping the future of drilling technology.

- Digitalization & Data Analytics:

The rotary blasthole drilling rig market is experiencing a significant shift towards digitalization and the integration of data analytics. The ability to collect, analyze, and interpret real-time drilling data is becoming increasingly crucial for optimizing drilling operations and improving overall productivity. Drilling rigs are now equipped with advanced sensors, data loggers, and communication systems that enable the collection of data on various parameters, including drilling depth, penetration rate, and rock formation characteristics. This data is then analyzed using sophisticated software tools to identify trends, optimize drilling parameters, and predict potential issues. Furthermore, the integration of digital twin technology allows for the creation of virtual models of drilling operations, enabling mining companies to simulate and optimize drilling processes before implementation. The use of predictive maintenance algorithms is also enabling mining companies to anticipate and prevent equipment failures, reducing downtime and maintenance costs. As the mining industry continues to embrace digitalization, the adoption of data analytics and digital technologies will become increasingly crucial for the rotary blasthole drilling rig market, driving innovation and enabling more efficient and sustainable mining operations.

Leading Companies Operating in the Global Rotary Blasthole Drilling Rig Industry:

Bauer AG, Caterpillar Inc.

Epiroc AB

Komatsu Ltd.

Liebherr Group

Nanchang Kamach Mining Co. Ltd.

Sandvik AB

Schramm Inc.

Sunward Intelligent Equipment Co. Ltd

Rotary Blasthole Drilling Rig Market Report Segmentation:

By Type:

Large-range Drilling Rig

Mid-range Drilling Rig

Others

Large-range drilling rig represents the largest segment as its high capacity and efficiency are essential for the extensive and deep drilling requirements of major industrial projects, particularly in mining and large-scale construction.

By Power:

Electric

Diesel

Hybrid

Based on the power, the market has been classified into electric, diesel, and hybrid.

By Application:

Quarries

Open-Pit Mining

Others

Open-pit mining exhibits a clear dominance in the market owing to its reliance on rotary blasthole drilling rigs for its operations, as these rigs provide the necessary depth and precision to efficiently extract minerals from large surface mines.

Regional Insights:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Asia Pacific enjoys the leading position in the rotary blasthole drilling rig market due to rapid industrialization, extensive mining activities, and significant investments in infrastructure development across countries like China, India, and Australia.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145