What Are Uniaxial Geogrids?

Uniaxial geogrids are geosynthetic materials designed to provide strength and stability to soil structures primarily in one direction17. These geogrids are characterized by their high tensile strength in a single, longitudinal direction, making them ideal for applications where reinforcement is required along a specific axis24. Uniaxial geogrid exporters in Ahmedabad Unlike biaxial geogrids, which offer strength in two directions, uniaxial geogrids are engineered to withstand tension and distribute loads in a single plane1.

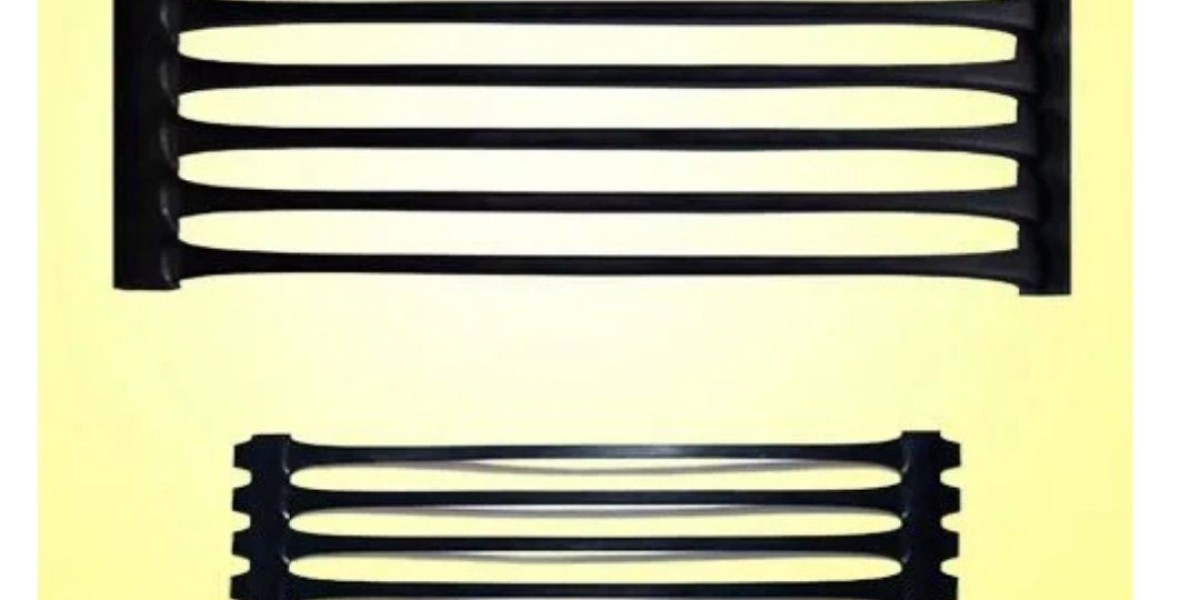

Composition and Structure

Typically constructed from high-density polyethylene (HDPE) or polyester yarns with a PVC or similar coating, uniaxial geogrids feature a distinct grid-like structure with long, narrow ribs12. The apertures, or openings, Uniaxial geogrid manufacturers in Ahmedabad within the grid allow for soil particles to interlock with the geogrid, creating a mechanical bond that enhances soil reinforcement2. The ribs, running in the machine direction, provide stiffness and structural integrity, while the junctions facilitate load transfer between adjacent ribs2. This design ensures that the geogrid can effectively resist tensile forces and maintain its load-bearing capacity over time2.

How Uniaxial Geogrids Work

The primary function of uniaxial geogrids is to reinforce soil by interlocking with the surrounding soil particles12. When soil is placed over the geogrid, it passes through the apertures, creating a strong mechanical connection2. This interlock prevents soil movement and provides stability to the structure2. By distributing loads along the geogrid, uniaxial geogrids reduce stress concentration in the soil, minimizing deformation and increasing the overall strength of the reinforced soil mass1. Uniaxial geogrid exporters in India The "strength is in the length," meaning it should be rolled out perpendicular to the face of the wall or slope to the appropriate length based on the engineered plans1.

Advantages of Using Uniaxial Geogrids

Uniaxial geogrids offer several advantages in construction and civil engineering projects1:

High Tensile Strength: They possess exceptional tensile strength in one direction, enabling them to withstand significant loads and distribute forces effectively2.

Soil Stabilization: They enhance soil stability by interlocking with soil particles, preventing soil movement and improving load-bearing capacity2.

Cost-Effectiveness: Due to their simple construction, uniaxial geogrids are economical compared to other reinforcement methods1.

Durability: They are designed to resist environmental factors such as chemical attack, UV degradation, and biological degradation, ensuring long-term performance2.

Easy Installation: Supplied in roll form, uniaxial geogrids are easy to transport, handle, and install, reducing construction time and labor costs2.

Environmental Benefits: Uniaxial geogrids help prevent soil erosion and reduce the need for extensive excavation, making them an environmentally friendly solution1.

Applications of Uniaxial Geogrids

Uniaxial geogrids are versatile and can be used in a variety of applications1:

Retaining Walls: They provide reinforcement to retaining walls, enhancing their stability and preventing soil collapse13.

Embankments: Uniaxial geogrids are used to stabilize embankments, particularly those constructed on soft or unstable soils13.

Slope Stabilization: They reinforce steep slopes, preventing soil erosion and landslides13.

Landfill Systems: Uniaxial geogrids are incorporated into landfill liner systems to provide stability and prevent differential settlement13.

Bridge Abutments: They offer reinforcement in bridge abutments, especially where forces are applied in one direction4.

Geogrid Reinforced Earth Systems: They are suited for geogrid reinforced earth systems1.

Uniaxial vs. Biaxial Geogrids

The key difference between uniaxial and biaxial geogrids lies in their strength orientation145. Uniaxial geogrids provide strength in one direction, making them suitable for applications requiring reinforcement along a specific axis, such as retaining walls and steep slopes45. Biaxial geogrids, on the other hand, offer strength in two directions, distributing forces more evenly and providing greater support for the soil in all directions145. Biaxial geogrids are ideal for applications such as road construction and soil stabilization, where loads are applied in multiple directions1.

Installation Techniques

Proper installation is crucial to ensure the effectiveness of uniaxial geogrids2. The following steps outline a typical installation process:

Site Preparation: Prepare the site by clearing vegetation, debris, and any unstable soil2.

Grading: Grade the soil surface to create a smooth and level base for the geogrid2.

Geogrid Placement: Unroll the uniaxial geogrid perpendicular to the slope or wall face, ensuring it is aligned with the primary direction of reinforcement1.

Overlapping: Overlap adjacent geogrid layers according to the manufacturer's recommendations2.

Backfilling: Place soil over the geogrid, ensuring it fills the apertures and creates a strong mechanical interlock12.

Compaction: Compact the soil in layers to achieve the desired density and stability1.

Facing: Install a facing system, such as segmental retaining wall blocks or welded wire forms, to protect the reinforced soil structure1.

Factors to Consider When Selecting Uniaxial Geogrids

When selecting uniaxial geogrids for a specific project, consider the following factors:

Tensile Strength: Ensure the geogrid has sufficient tensile strength to withstand the anticipated loads2.

Aperture Size: Choose a geogrid with an appropriate aperture size to allow for proper soil interlock2.

Material Type: Select a material that is compatible with the soil conditions and resistant to environmental degradation12.

Manufacturer Specifications: Refer to the manufacturer's technical specifications and guidelines for detailed information about the geogrid product2.

Project Requirements: Consider the specific requirements of the project, such as the height and slope of the structure, soil type, and anticipated loads1.

The Role of Ahmedabad in the Uniaxial Geogrid Market

Ahmedabad, a major industrial hub in India, plays a significant role in the manufacturing and export of geosynthetic materials, including uniaxial geogrids. Several companies in Ahmedabad specialize in the production and supply of high-quality uniaxial geogrids for various applications3. These companies contribute to the growing demand for soil reinforcement solutions in India and abroad. As leading Uniaxial geogrid manufacturers in Ahmedabad, these firms adhere to international standards, ensuring the reliability and effectiveness of their products. The presence of Uniaxial geogrid exporters in Ahmedabad facilitates the distribution of these materials to projects across the globe. Furthermore, numerous Uniaxial geogrid exporters in India leverage Ahmedabad's strategic location and manufacturing capabilities to serve international markets, making the city a key player in the geosynthetics industry.

Future Trends in Uniaxial Geogrid Technology

The field of uniaxial geogrid technology is continuously evolving, with ongoing research and development focused on improving performance, sustainability, and cost-effectiveness. Some emerging trends include:

Biopolymers: The use of biopolymers in geogrid manufacturing to reduce reliance on fossil fuels and enhance environmental sustainability.

Nanotechnology: Incorporating nanomaterials into geogrids to improve their mechanical properties and durability.

Smart Geogrids: Developing geogrids with embedded sensors to monitor soil conditions and structural performance in real-time.

Customized Designs: Tailoring geogrid designs to meet the specific requirements of individual projects, optimizing performance and reducing material waste.

Conclusion

Uniaxial geogrids are essential tools for soil reinforcement and stabilization in a wide range of civil engineering applications. Their high tensile strength, durability, and ease of installation make them a cost-effective and environmentally friendly solution for enhancing the stability of retaining walls, embankments, slopes, and other soil structures12. As technology advances, uniaxial geogrids are expected to play an increasingly important role in sustainable infrastructure development, ensuring the safety and longevity of civil engineering projects worldwide1.

FAQ

What is the lifespan of a uniaxial geogrid?

The lifespan of a uniaxial geogrid depends on factors such as material type, soil conditions, and environmental exposure. However, high-quality geogrids are designed to resist chemical attack, UV degradation, and biological degradation, ensuring long-term performance in various soil conditions2. With proper installation and maintenance, uniaxial geogrids can last for several decades, providing reliable soil reinforcement and stability2.

Can uniaxial geogrids be used in wet or submerged conditions?

Yes, uniaxial geogrids can be used in wet or submerged conditions, provided they are made from materials that are resistant to water damage and chemical degradation2. It is important to select a geogrid that is specifically designed for use in such environments and to follow the manufacturer's recommendations for installation and maintenance2. Additionally, proper drainage systems should be implemented to prevent water accumulation and ensure the long-term performance of the geogrid1.

Are uniaxial geogrids recyclable?

Many uniaxial geogrids are made from recyclable materials such as high-density polyethylene (HDPE) or polyester2. However, the recyclability of a specific geogrid product depends on its composition and the availability of recycling facilities in the area2. Consult the manufacturer's specifications and local recycling guidelines to determine whether a particular uniaxial geogrid is recyclable and how to properly dispose of it at the end of its service life2.