In today’s rapidly advancing manufacturing world, efficiency, precision, and automation are key to staying competitive. One area where these factors are having a significant impact is in the production of plastic bottles, with the automatic bottle blowing machine market taking center stage. These machines, which create hollow plastic bottles from pre-formed molds, are critical in industries ranging from beverages to pharmaceuticals. In this blog, we will explore the growth, key trends, and future prospects of the automatic bottle blowing machine market.

What is an Automatic Bottle Blowing Machine?

Automatic bottle blowing machines are industrial devices used to produce plastic bottles in large volumes. The process involves taking plastic parisons (hollow pre-forms) made of materials like PET (Polyethylene Terephthalate) or HDPE (High-Density Polyethylene) and transforming them into bottles of various shapes and sizes through a blowing process.

The machine operates in several steps:

- Heating: The pre-forms are heated to the right temperature to become pliable.

- Stretching and Blowing: The heated pre-forms are placed into molds, stretched, and air is blown into them to take the shape of the mold.

- Cooling: Once the bottle reaches its desired shape, it is cooled down and ready for use.

Automatic bottle blowing machines are designed for high-volume production, offering precision and speed while reducing labor costs and improving overall productivity.

The Growth of the Automatic Bottle Blowing Machine Market

The global automatic bottle blowing machine market has experienced significant growth over the past few years, driven by increased demand for packaged products, especially in the food and beverage, pharmaceutical, and cosmetics industries. The market is expected to continue expanding due to a few key factors:

- Rising Demand for Bottled Beverages: With an increasing global population and growing demand for bottled beverages like water, soft drinks, and juices, manufacturers are investing heavily in high-efficiency bottle production systems.

- Demand for Eco-Friendly Packaging: The push for sustainable packaging is influencing the market. PET, commonly used for bottle production, is recyclable and lightweight, making it an attractive choice for environmentally-conscious brands. Moreover, new developments in bio-based plastics and plant-based polymers are pushing the boundaries of sustainable packaging, driving innovation in the machine manufacturing sector.

- Technological Advancements: Automation in bottle blowing machines has led to improved speed, precision, and energy efficiency. Integration of advanced features like programmable controllers, real-time monitoring, and robotic systems has enhanced the productivity and accuracy of bottle production, further fueling market growth.

- Cost-Effective Manufacturing: Automatic bottle blowing machines reduce the need for manual labor, offering cost savings for manufacturers. The machines provide high-volume production with minimal human intervention, making them ideal for large-scale production environments.

Key Market Segments

The automatic bottle blowing machine market can be segmented based on various factors such as machine type, bottle capacity, end-use industry, and region. Let’s explore these segments:

- Machine Type

- Extrusion Blow Molding Machines: These machines are used for producing large, hollow bottles and containers, typically for the automotive, packaging, and industrial sectors.

- Injection Blow Molding Machines: Commonly used for small-volume, high-precision applications, such as pharmaceutical and cosmetic bottles.

- Stretch Blow Molding Machines: The most common machine for producing PET bottles, especially for beverages. These machines offer high-speed production with better control over the bottle’s strength and shape.

- Bottle Capacity

- Small Capacity Bottles (up to 1L): Bottles used in the beverage and cosmetics industries, especially for products like water, juices, and personal care items.

- Medium Capacity Bottles (1L to 5L): Bottles for beverages, household cleaners, and chemicals.

- Large Capacity Bottles (over 5L): Typically used in industries like food processing, chemicals, and bulk beverages.

- End-Use Industry

- Food and Beverage: The largest segment, driven by the increasing consumption of bottled water, carbonated drinks, juices, and more.

- Pharmaceuticals: With stringent quality control requirements, the pharmaceutical industry requires highly accurate and hygienic bottle production systems.

- Cosmetics and Personal Care: High demand for personalized, aesthetically appealing packaging has led to significant growth in the cosmetic bottle segment.

- Others: Includes applications in the chemical, automotive, and industrial sectors, where large containers are required.

Request a sample@ https://www.econmarketresearch.com/request-sample/EMR00667/

Key Market Trends and Innovations

The automatic bottle blowing machine market is evolving, with numerous innovations and trends shaping its future:

- Smart Automation: As industries look to increase their operational efficiency, automation is becoming more sophisticated. Smart blow molding machines that incorporate Internet of Things (IoT) technology and advanced sensors are allowing manufacturers to monitor production in real time, ensuring the highest standards of quality and reducing downtime.

- Energy-Efficient Machines: With rising energy costs and sustainability concerns, manufacturers are developing energy-efficient bottle blowing machines. These machines consume less electricity and use advanced cooling systems to reduce energy waste, making them more environmentally friendly and cost-effective in the long run.

- Integration of AI and Machine Learning: Artificial intelligence is being integrated into automatic bottle blowing machines to improve predictive maintenance, quality control, and optimize production processes. Machine learning algorithms can detect and correct potential issues before they affect production, minimizing waste and downtime.

- Focus on Sustainability: As consumers and businesses increasingly prioritize sustainability, automatic bottle blowing machine manufacturers are exploring the use of alternative materials such as biodegradable plastics, plant-based polymers, and recycled PET to create eco-friendly bottles. This trend is also being supported by the development of machines capable of handling these new materials.

- Customization and Flexibility: To meet the needs of a growing and diverse consumer market, automatic bottle blowing machines are becoming more flexible, capable of producing bottles in a variety of shapes, sizes, and designs. Customization options are particularly beneficial in industries like cosmetics, where packaging plays a significant role in branding.

Regional Insights

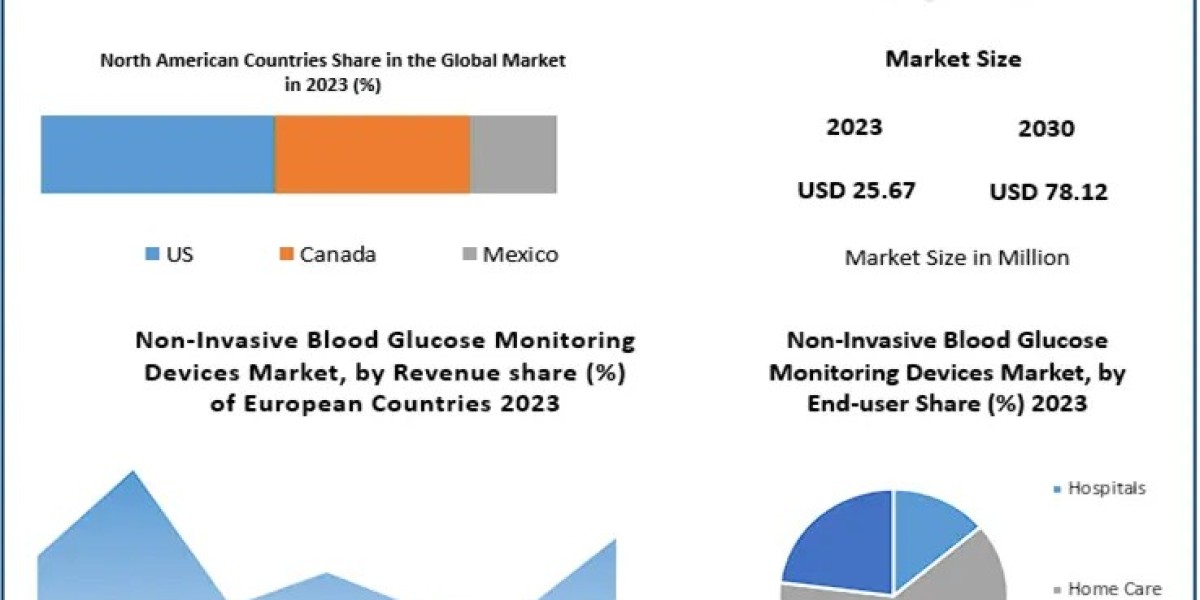

The demand for automatic bottle blowing machines varies by region, with Asia-Pacific, North America, and Europe being the key players in the market.

- Asia-Pacific: This region dominates the market, driven by the rapid growth of manufacturing and packaging industries in countries like China, India, and Japan. High demand for consumer goods, beverages, and packaged food products in this region is contributing to the increased use of automatic bottle blowing machines.

- North America: The North American market is driven by advancements in manufacturing technologies, sustainability initiatives, and high demand from the food and beverage industry.

- Europe: Europe is witnessing steady growth in the market, with an increasing emphasis on eco-friendly packaging and automation in manufacturing processes.

Email: [email protected]