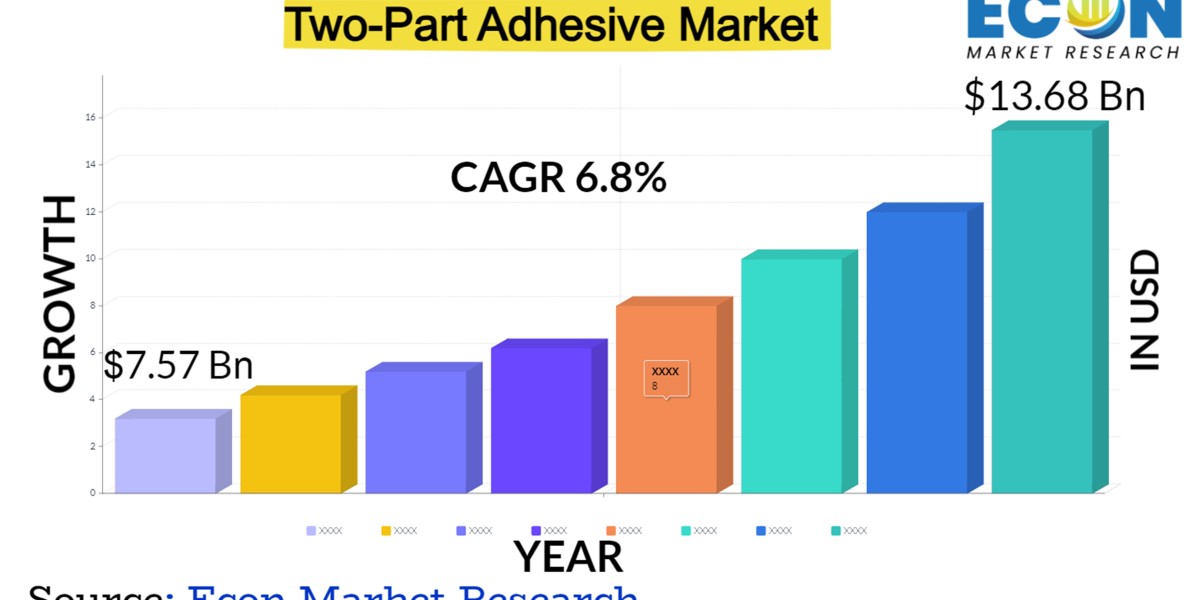

The Growing Demand for Two-Part Adhesives in Industrial Applications

In today’s fast-paced industrial landscape, two-part adhesives are gaining momentum as a go-to solution for manufacturers seeking strong, durable, and reliable bonding methods. The two-part adhesive market has witnessed significant growth, driven by advancements in technology, increasing adoption across diverse industries, and the need for high-performance materials in modern applications. In this blog, we’ll explore the key trends, applications, and factors propelling the growth of this versatile adhesive segment.

What Are Two-Part Adhesives?

Two-part adhesives, also known as two-component adhesives, consist of a resin and a hardener that are mixed together before application. Once combined, the chemical reaction between the two components results in a strong and durable bond. These adhesives are renowned for their ability to bond various materials such as metals, plastics, composites, and ceramics, making them a preferred choice in industries like automotive, aerospace, construction, electronics, and medical devices.

Request a sample@ https://www.econmarketresearch.com/industry-report/two-part-adhesive-market/

Key Trends Driving the Market Growth

- Innovation in Formulations: Advancements in adhesive chemistry have led to the development of specialized two-part adhesives with improved properties such as faster curing times, enhanced thermal resistance, and increased flexibility. These innovations cater to the evolving needs of industries requiring customized bonding solutions.

- Sustainability Focus: With a growing emphasis on environmentally friendly manufacturing practices, companies are developing two-part adhesives with reduced volatile organic compounds (VOCs) and improved energy efficiency during curing. These adhesives support sustainability goals without compromising performance.

- Rising Demand in Automotive and Aerospace: Lightweight materials like carbon fiber and aluminum are increasingly used in automotive and aerospace sectors to improve fuel efficiency. Two-part adhesives play a critical role in bonding these materials while maintaining structural integrity, reducing weight, and enhancing durability.

- Growth in Electronics and Medical Devices: As electronics become more compact and medical devices more sophisticated, the need for adhesives with precise application and excellent performance under extreme conditions has surged. Two-part adhesives are ideal for these applications due to their exceptional bonding strength and versatility.

Key Applications of Two-Part Adhesives

- Automotive and Aerospace: Used for structural bonding, sealing, and assembly of lightweight components.

- Construction: Ideal for bonding materials like glass, metal, and concrete in architectural projects.

- Electronics: Essential for encapsulation, potting, and component bonding in circuit boards and devices.

- Medical Devices: Used for assembling surgical instruments, diagnostic equipment, and wearable devices.

Challenges and Opportunities

While the two-part adhesive market shows immense promise, challenges such as the high cost of advanced formulations and the need for precise mixing and application methods remain. However, these challenges also create opportunities for innovation in dispensing systems, automation, and cost-effective formulations. Moreover, increasing investments in research and development by key players are expected to unlock new possibilities, further expanding the market.

Email: sales@econmarketresearch.com