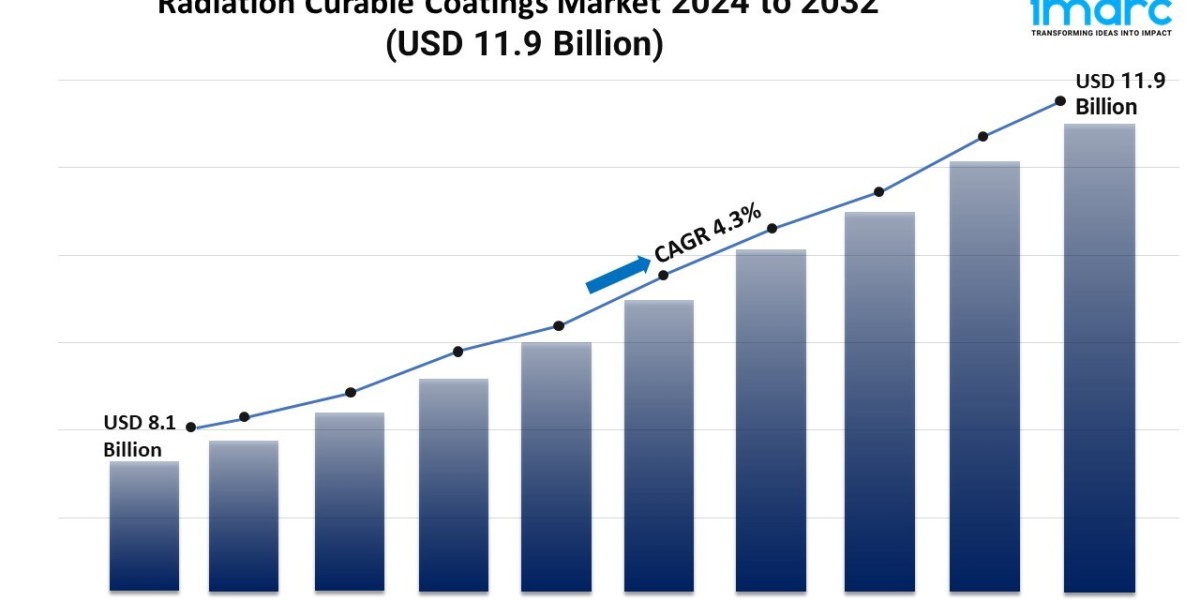

Global Radiation Curable Coatings Market Statistics: USD 11.9 Billion Value by 2032

Radiation Curable Coatings Industry

Summary:

- The global radiation curable coatings market size reached USD 8.1 Billion in 2023.

- The market is expected to reach USD 11.9 Billion by 2032, exhibiting a growth rate (CAGR) of 4.3% during 2024-2032.

- Asia Pacific leads the market, accounting for the largest radiation curable coatings market share.

- Based on the ingredient, the market has been divided into oligomers, monomers, photoinitiators, and additives.

- On the basis of the type, the market has been bifurcated into ultraviolet curing and electron beam curing.

- Based on the application, the market has been categorized into paper and film, printing inks, plastics, wood, glass, and others.

- The rise in the emphasis on environmental regulations and sustainability is a primary driver of the radiation curable coatings market.

- Advancements in radiation curing technologies are reshaping the radiation curable coatings market.

Industry Trends and Drivers:

- Environmental Regulations and Sustainability Demands:

The increasing emphasis on environmental regulations and sustainability is impelling the growth of the market. Traditional solvent-based coatings often contain volatile organic compounds (VOCs), which contribute to air pollution and pose health risks. Governments and regulatory bodies worldwide are imposing stricter limits on VOC emissions, encouraging industries to adopt more eco-friendly alternatives. Radiation curable coatings, which include ultraviolet (UV) and electron beam (EB) curing technologies, offer a solvent-free solution that significantly reduces VOC emissions. Additionally, these coatings typically require less energy and produce minimal waste, aligning with global sustainability goals. Manufacturers are motivated to switch to radiation curable systems not only to comply with regulations but also to meet the growing consumer demand for green products. This shift is particularly evident in sectors like automotive, electronics, and packaging, where there is a strong push towards reducing environmental footprints.

- Technological Advancements and Improved Performance:

Advancements in radiation curing technologies are significantly enhancing the performance and applicability of radiation curable coatings. Innovations in UV and electron beam (EB) curing systems have led to faster curing times, higher efficiency, and improved coating properties, such as hardness, adhesion, and resistance to chemicals and abrasion. These technological improvements make radiation curable coatings highly attractive for various industrial applications, including automotive, electronics, medical devices, and packaging. Moreover, in the automotive industry, the quick curing process accelerates production lines and reduces manufacturing costs while providing durable and high-quality finishes. In electronics, the precise curing capabilities ensure reliable performance of coatings on sensitive components. Additionally, the ability to tailor formulations to meet specific requirements is expanding the versatility of radiation curable coatings.

- Growing Demand in High-Performance Industries:

The increasing demand from high-performance industries is bolstering the market growth. Sectors, such as automotive, electronics, aerospace, and medical devices require coatings that offer superior performance characteristics, including durability, chemical resistance, and aesthetic appeal. Radiation curable coatings meet these stringent requirements by providing fast curing times, excellent adhesion, and the ability to form robust protective layers. In the automotive industry, these coatings are used for clear coats, primers, and functional finishes that enhance vehicle appearance and longevity. In the electronics sector, radiation curable coatings are essential for protecting components from environmental factors and ensuring reliable operation. The aerospace industry benefits from lightweight and high-strength coatings that contribute to fuel efficiency and performance. Additionally, the medical device industry relies on radiation curable coatings for biocompatible and sterilizable surfaces.

Request for a sample copy of this report: https://www.imarcgroup.com/radiation-curable-coatings-market/requestsample

Radiation Curable Coatings Market Report Segmentation:

Breakup By Ingredient:

- Oligomers

- Monomers

- Photoinitiators

- Additives

Based on the ingredient, the market has been divided into oligomers, monomers, photoinitiators, and additives.

Breakup By Type:

- Ultraviolet Curing

- Electron Beam Curing

On the basis of the type, the market has been bifurcated into ultraviolet curing and electron beam curing.

Breakup By Application:

- Paper and Film

- Printing Inks

- Plastics

- Wood

- Glass

- Others

Based on the application, the market has been categorized into paper and film, printing inks, plastics, wood, glass, and others.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific's dominance in the radiation curable coatings market is attributed to its stringent environmental regulations, advanced industrial sectors, such as automotive and electronics, and a strong emphasis on sustainable and eco-friendly manufacturing practices.

Top Radiation Curable Coatings Market Leaders:

The radiation curable coatings market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- 3M Company

- Akzo Nobel N.V.

- Allnex (PTT Global Chemical Public Company Limited)

- Ashland Global Specialty Chemicals Inc.

- Axalta Coating Systems Ltd.

- BASF SE, DIC Corporation

- Dymax Corporation

- Evonik Industries AG

- Momentive Performance Materials Inc.

- PPG Industries Inc.

- The Sherwin-Williams Company.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163