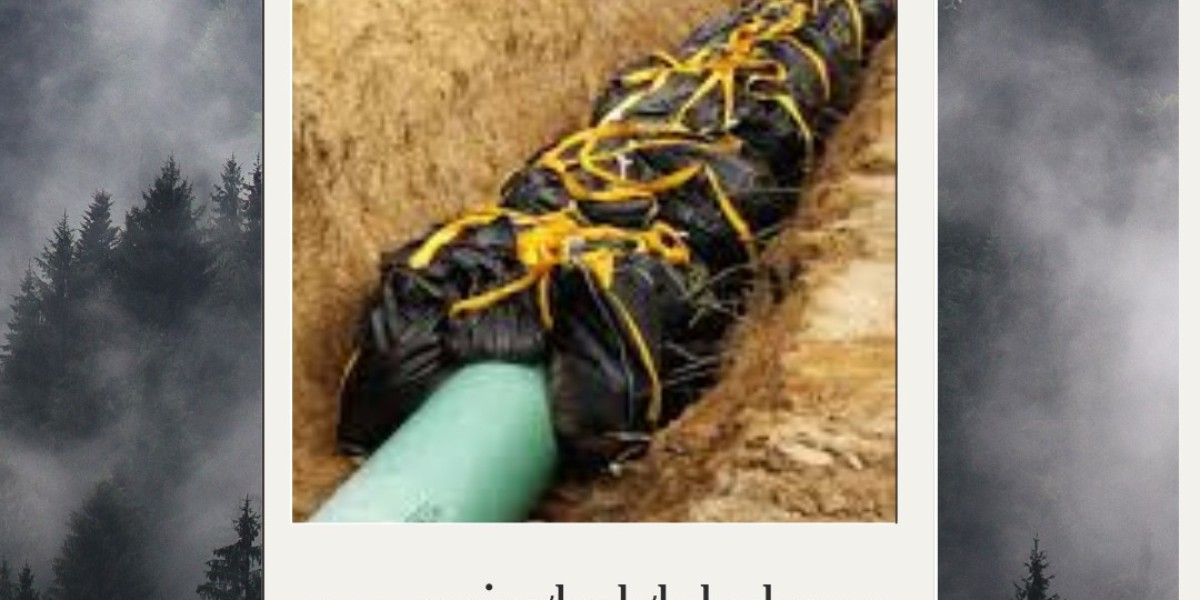

Pipeline weight bags are essential tools used in the construction and maintenance of pipelines. These bags provide the necessary weight to ensure that pipelines remain submerged in water and do not float away. The importance of having a secure and stable pipeline cannot be overstated, as it prevents environmental hazards and ensures efficient transportation of fluids. As industries increasingly adopt these solutions, understanding their benefits and applications is crucial for efficient pipeline management.

Pipeline Weight Bags: Versatility and Applications

Pipeline weight bags offer versatility in their applications. They are used in various environments, including rivers, lakes, and oceans. The design of these bags allows them to hold a significant amount of water, providing the weight needed to anchor pipelines effectively. The ability to adjust the weight by adding or removing water makes these bags ideal for various projects, from construction to maintenance. This flexibility ensures that they can meet the unique requirements of different pipeline installations, making them a go-to solution for many professionals in the field.

River Weights for Pipelines: A Specialized Solution

When it comes to underwater installations, River weights for pipelines are particularly effective. These weights are specifically designed to operate in river environments, where the flow of water can pose challenges to pipeline stability. The use of river weights ensures that pipelines stay in place, preventing them from being displaced by strong currents or floating debris. This specialized solution not only enhances the safety of the pipeline but also minimizes the risk of environmental contamination, which is crucial in protecting aquatic ecosystems.

Choosing the Right Weight Bag in India

In India, the demand for weight bags has surged as various industries expand their pipeline networks. When choosing a weight bag in India, several factors should be considered. The material of the bag, its weight capacity, and its design are essential elements that affect performance. For instance, heavy-duty materials that can withstand harsh environmental conditions are preferable for long-term applications. Additionally, the weight capacity should align with the specific requirements of the pipeline installation, ensuring that the bag can provide adequate support.

Durability and Longevity of Pipeline Weight Bags

Durability is a significant factor in the performance of pipeline weight bags. These bags are often exposed to various environmental conditions, including extreme temperatures, moisture, and physical stress. Therefore, investing in high-quality bags made from durable materials is crucial for ensuring their longevity. Bags that resist punctures, tears, and UV degradation will perform better over time, providing a reliable solution for pipeline anchoring. This durability is particularly important in regions with fluctuating weather patterns, where pipelines are subjected to varying stresses.

Innovative Designs in Pipeline Weight Bags

The design of pipeline weight bags has evolved over the years, incorporating innovative features that enhance their effectiveness. Many modern bags are equipped with multiple compartments, allowing for adjustable weight distribution. This feature enables users to customize the weight according to their specific needs, enhancing the bag’s versatility. Furthermore, the introduction of lightweight materials has made these bags easier to handle and transport, reducing labor costs associated with installation and maintenance.

Environmental Considerations for Pipeline Weight Bags

Environmental sustainability is becoming increasingly important in all industries, including pipeline management. Many manufacturers are now producing eco-friendly pipeline weight bags that minimize environmental impact. These bags are made from recyclable materials, ensuring that they do not contribute to pollution or waste. Additionally, using weight bags can reduce the need for concrete or steel anchors, which are resource-intensive to produce. By choosing environmentally friendly options, companies can align their operations with sustainable practices while maintaining efficiency.

Cost-Effectiveness of Using Pipeline Weight Bags

Cost-effectiveness is another significant advantage of using pipeline weight bags. Compared to traditional anchoring methods, such as concrete blocks or steel weights, Weight bag in India often provide a more economical solution. The initial investment in weight bags is typically lower, and their ease of use can reduce labor costs during installation. Moreover, their lightweight nature means that transportation costs are minimized, making them a practical choice for companies looking to optimize their budget while ensuring safety and compliance.

Safety Features of Pipeline Weight Bags

Safety is paramount in any construction or maintenance project, and pipeline weight bags contribute to a safer working environment. The proper use of these bags ensures that pipelines are anchored securely, reducing the risk of accidents or spills. Additionally, many manufacturers incorporate safety features into their bag designs, such as reflective strips or bright colors, which enhance visibility during installation. This attention to safety helps workers to identify potential hazards quickly and take appropriate action, fostering a safer workplace.

Training and Best Practices for Using Pipeline Weight Bags

To maximize the effectiveness of pipeline weight bags, training and adherence to best practices are essential. Workers involved in the installation and maintenance of pipelines should receive proper training on how to use these bags effectively. Understanding the correct methods for filling, placing, and securing weight bags can significantly impact the overall success of the project. Companies should also develop best practices that outline the steps to follow when using weight bags, ensuring consistency and reliability across different projects.

Case Studies: Successful Implementation of Pipeline Weight Bags

Numerous case studies illustrate the successful implementation of pipeline weight bags in various industries. For instance, in a recent project involving the installation of a new pipeline in a river, contractors utilized river weights for pipelines to secure the structure against strong currents. The project was completed ahead of schedule and within budget, highlighting the effectiveness of using weight bags in challenging environments. Such success stories serve as valuable references for other companies considering pipeline weight solutions.

Future Trends in Pipeline Weight Solutions

As technology continues to advance, the future of pipeline weight solutions looks promising. Innovations in materials and designs will likely lead to even more effective and sustainable weight bags. For example, the development of smart weight bags equipped with sensors could provide real-time data on the weight distribution and stability of pipelines. Such advancements would enable companies to monitor their installations more effectively, ensuring that any issues are addressed promptly. The integration of technology into pipeline management is set to revolutionize the industry.

Conclusion: Embracing Efficient Weight Solutions

In conclusion, pipeline weight bags are invaluable tools for ensuring the stability and safety of pipeline installations. With their versatility, durability, and cost-effectiveness, these bags provide efficient weight solutions for various environments, including rivers and industrial applications. As industries continue to embrace innovative technologies and sustainable practices, the demand for Pipeline weight bags will likely grow. Companies in India and beyond should recognize the benefits of these solutions and invest in high-quality products that enhance their pipeline management efforts. By doing so, they will not only improve operational efficiency but also contribute to a safer and more sustainable future.

Frequently Asked Questions(FAQs)

1. Are pipeline weight bags environmentally friendly?

Many manufacturers are now producing eco-friendly pipeline weight bags made from recyclable materials. These bags can help reduce environmental impact compared to traditional anchoring methods, such as concrete or steel weights.

2. How do I fill pipeline weight bags?

Pipeline weight bags can typically be filled with water or sand. To fill them, simply open the bag, add the desired weight material, and then securely close the bag. If using water, make sure to seal the bag properly to prevent leaks.

3. What are river weights for pipelines?

River weights for pipelines are a specific type of pipeline weight bag designed for use in river environments. They are tailored to provide stability and prevent pipelines from being displaced by strong currents or floating debris.