When it comes to ensuring safety in hazardous environments, every detail matters. One of the most critical components in such settings is the Explosion Proof Cable Gland. These cable glands are specially designed to prevent explosions in dangerous areas where gases, vapors, or dust particles could ignite. In this blog, we will explain what explosion proof cable glands are, how they work, and why they are so important in industrial and safety applications. This article will also touch on the importance of using the best cable gland explosion proof products to ensure reliability and safety.

Understanding Explosion Proof Cable Glands

An Explosion Proof Cable Gland is a device used to secure and protect electrical cables where there’s a risk of explosion. These glands play an essential role in ensuring that hazardous gases or particles don’t enter or exit an enclosure, preventing the risk of explosion caused by sparks, short circuits, or heat generated by electrical equipment.

Explosion proof cable glands are typically used in industries such as oil and gas, chemical manufacturing, mining, and marine environments. In these industries, the presence of flammable gases, liquids, or dust can create an environment prone to explosions, and using regular cable glands would not provide the necessary level of protection.

How Do Explosion Proof Cable Glands Work?

Explosion proof cable glands work by creating a barrier between the potentially dangerous environment and the electrical enclosure. They achieve this by sealing the cable's entry point to ensure that no flammable gases, dust, or liquids can pass through the enclosure. This process ensures that any sparks or heat produced within the enclosure are contained and do not come into contact with the hazardous external atmosphere.

The materials used to construct explosion proof cable glands are also designed to withstand high temperatures, corrosion, and extreme environmental conditions, further enhancing safety.

These glands are tested and certified to ensure they meet the strict standards required for explosion protection. The certification process typically involves rigorous testing to verify that the cable gland can withstand pressure, heat, and other factors that could lead to an explosion in hazardous areas.

Types of Explosion Proof Cable Glands

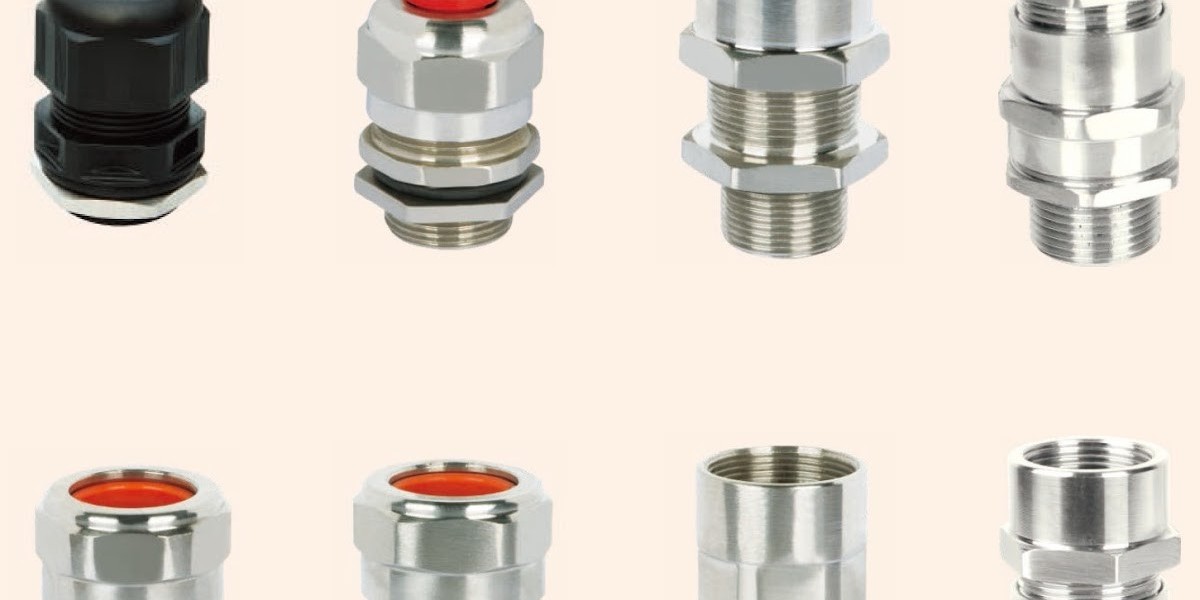

There are various types of explosion proof cable glands, each designed for different types of cables and applications. Some of the most common types include:

Threaded Explosion Proof Cable Glands: These are screwed directly into the equipment, providing a secure and tight seal that prevents the escape of gases or entry of contaminants.

Compression Type Glands: These glands work by compressing the cable to form a tight seal. They are often used for armored cables and provide an excellent level of protection in hazardous environments.

Sealing Glands: These cable glands include additional seals that provide an extra layer of protection in environments with high levels of moisture or dust.

Each type of gland offers unique benefits and is suited to specific applications. When selecting a cable gland explosion proof solution, it’s essential to consider the type of cable being used, the environmental conditions, and the level of protection required.

Why Are Explosion Proof Cable Glands Important?

The primary reason for using explosion proof cable glands is to ensure the safety of people and property in hazardous environments. Without proper protection, electrical equipment can become a significant risk, leading to costly damage, injuries, or even fatalities.

Here are a few reasons why explosion proof cable glands are essential:

Preventing Explosions: The primary purpose of these glands is to prevent the ignition of flammable materials in dangerous environments. By providing a secure barrier between the cable and the environment, explosion proof cable glands minimize the risk of sparks or heat causing an explosion.

Protecting Equipment: Hazardous environments can damage electrical equipment over time, leading to failures that could trigger explosions. Explosion proof cable glands protect the cables and equipment from external factors like dust, moisture, and heat.

Ensuring Compliance with Safety Standards: Industries operating in hazardous environments are required to comply with strict safety regulations. Using certified explosion proof cable glands helps ensure compliance with these regulations, reducing the risk of penalties and legal issues.

Durability: Explosion proof cable glands are built to withstand harsh conditions. They are often made from materials like brass, stainless steel, and high-quality plastics that offer excellent resistance to corrosion, wear, and tear.

Where Are Explosion Proof Cable Glands Used?

Explosion proof cable glands are widely used across various industries where explosive atmospheres are a concern. These include:

Oil and Gas: In refineries, oil rigs, and other areas where flammable gases are present, explosion proof cable glands are essential for ensuring the safe operation of electrical equipment.

Chemical Plants: The handling and production of chemicals often create hazardous environments where gases and vapors can easily ignite. Explosion proof cable glands provide a critical barrier to prevent explosions in these settings.

Mining: The mining industry involves the extraction of materials from the earth, creating dust and particles that can ignite. Explosion proof cable glands are used to secure cables and equipment, ensuring safety.

Marine Environments: Ships and offshore platforms often operate in hazardous environments where flammable materials are present. Explosion proof cable glands are used to ensure the safe operation of electrical systems in these areas.

Key Considerations When Choosing Explosion Proof Cable Glands

When selecting an Explosion Proof Cable Gland for your application, there are several factors to consider:

Material: Cable glands are available in various materials, including brass, stainless steel, and plastic. The material you choose should be suitable for the environment in which the gland will be used. For example, stainless steel is ideal for corrosive environments, while brass offers excellent conductivity.

Cable Type: The type of cable being used will determine the type of gland required. Ensure the cable gland is compatible with the cable’s size, armor type, and insulation.

Certification: Ensure that the explosion proof cable gland is certified to meet the relevant safety standards for your industry. Common certifications include ATEX and IECEx, which indicate that the product has been tested for use in explosive atmospheres.

Temperature Resistance: Choose a cable gland that can withstand the temperature extremes of your environment. Some materials and designs are better suited to high or low temperatures, ensuring the gland remains functional in all conditions.

Conclusion

Explosion Proof Cable Glands are an essential safety component in any environment where the risk of explosion is present. Whether you’re working in the oil and gas, chemical, mining, or marine industries, using certified cable gland explosion proof solutions ensures the safety of both people and equipment. By selecting the right type of cable gland for your specific needs, you can create a secure and reliable electrical system that minimizes the risk of accidents in hazardous environments.